PARESH ENGINEERING COMPANY

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to PARESH ENGINEERING COMPANY

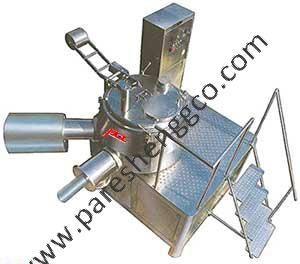

Attrition Mill

Mills are designed to produce high quality, superfine grinds over a very short period of time, using a minimum of energy and a minimum of floor space.

Advantages of the Attrition Mill Process

• Fine homogenous dispersions

Average particle sizes of 1 micron or less of solid bodies in high concentrations without entrapping air.

• Shorter grinding times

Up to ten times faster than conventional equipment, such as ball or pebble mills.

• No premixing

Ingredients may be added at the beginning or any other time during the process.

Corrections can be made without stopping the machine.

• Low power consumption

Due to favorable distribution of the installed energy, all power is used for grinding and dispersion.

• Minimum floor space

Attrition Mills are extremely compact in size and re¬quire no special foundations.

• Safe operation

Good checking possibilities and the stationary grinding chamber ensure safe operating conditions.

• Low maintenance

Simplicity of design and operation means minimum maintenance and downtime

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.